Category: Engineering Design

-

In-house product development at Chapco

Chapco’s dedicated team of in-house engineers ensures superior client satisfaction by seamlessly integrating design and production processes. With our expert engineers onboard, Chapco delivers exceptional value, enhancing outcomes for both the company and its clients.

-

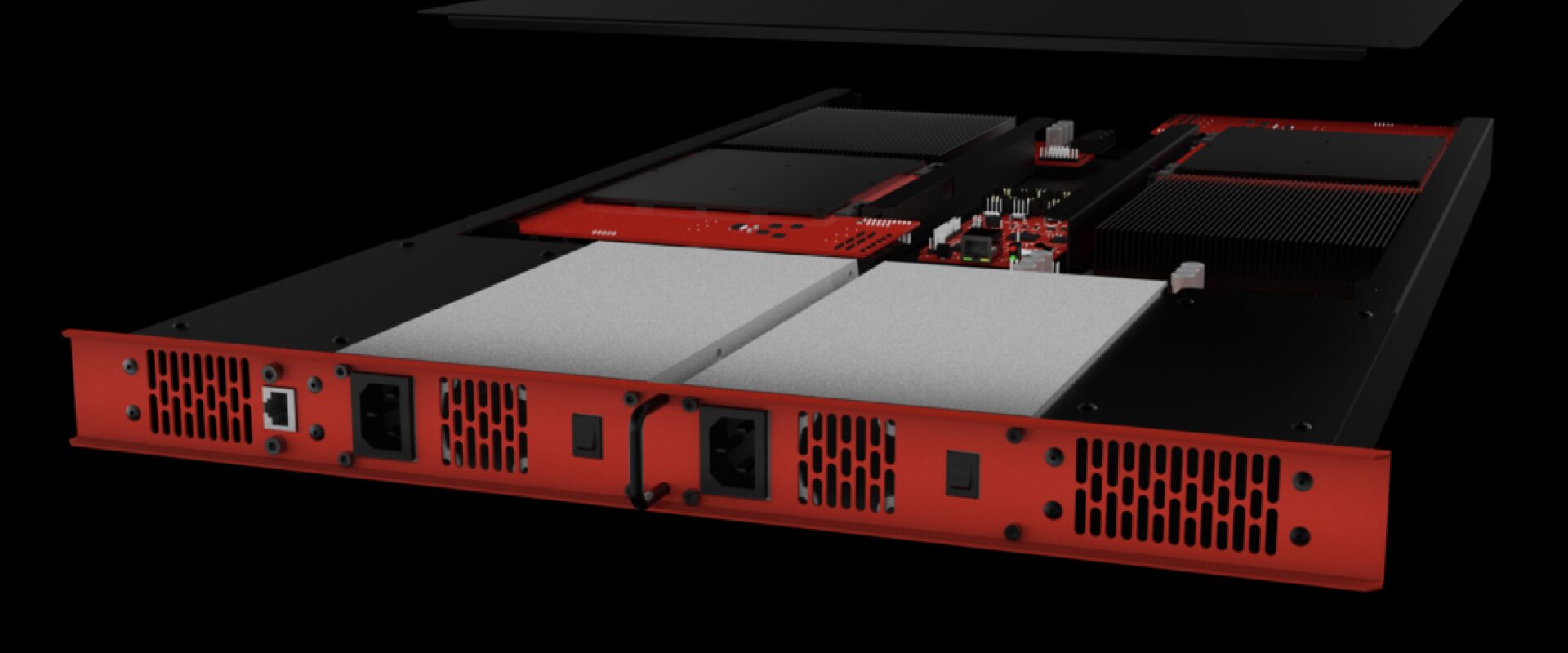

Chapco Ideaz & Obelisk®

Chapco Ideaz & Obelisk – a fabrication dream team: Cryptocurrency has been hailed as one of the next great technological revolutions, offering a critical pathway to transactional decentralization and security in a global cyber-economy that continues to evolve faster than many ever thought possible [Ideaz]