In-house product development at Chapco

Chapco’s dedicated team of

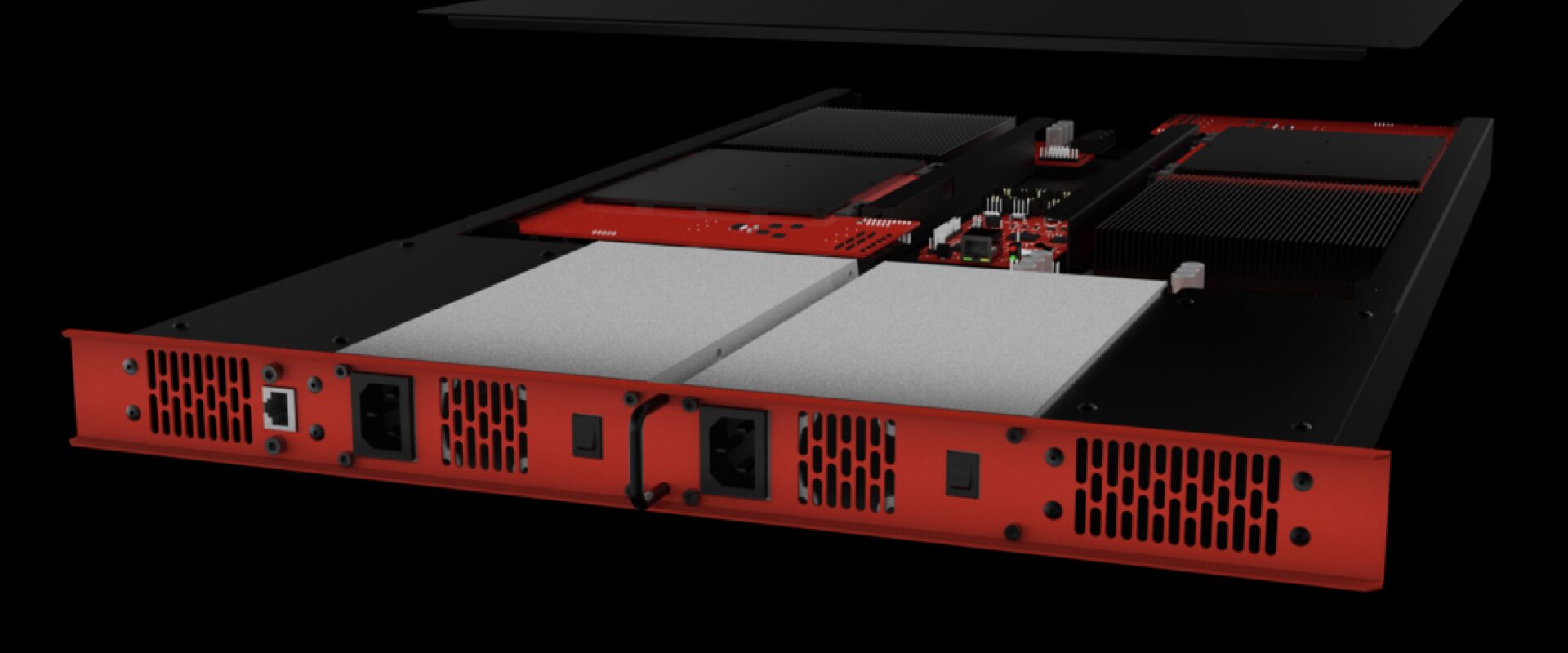

Chapco’s team offered value-added engineering services to ensure cost-effective manufacturing to meet our clients’ target pricing.

Following prototyping, Chapco was able to employ our automated work centers to ensure we met our clients’ aggressive time line

Images courtesy of Ideaz and Obelisk

Chapco’s dedicated team of

The position of Sheet Metal Technician Level 1 supports production by bending, fastening, assembling and performing secondary operations on metal products. Equipment includes but is not limited to spot welding, power press, PEM equipment, AccuPress, Strippit Press.

In the ever-evolving world of sheet metal manufacturing, staying ahead of the curve is not just a competitive advantage – it’s a necessity.