With our Automated Work Centers for Precision Fabrication, we pride ourselves on being able to handle any job, deliver on time, and guarantee the highest level of quality.

From prototype to production, we are your go-to custom metal fabrication experts.

Download our Capabilities Brochure

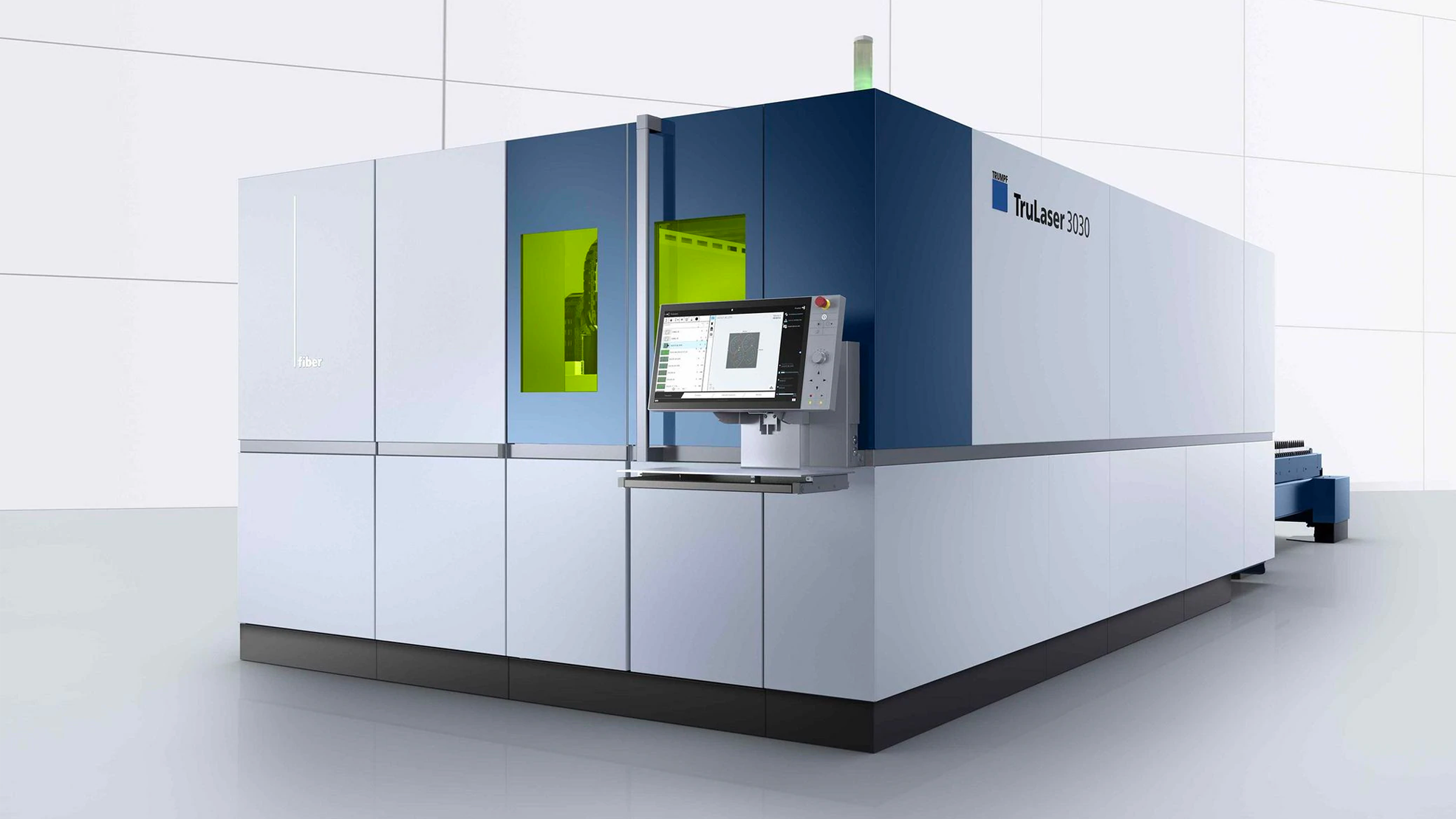

Cutting at 1,338 inches per minute, the Trudisk 3001, 300-Watt fiber-laser can cut multiple materials and thicknesses with no downtime for tooling changes.

The Trumatic’s integrated 20 ton punch/form features up to 900 strokes/minute, with deburring and scratch-free processing, to form complex features including:

High-performance production cell, solid-state laser enables the processing of non-ferrous metals and can handle thick and thin sheet. BrightLine fiber guarantees high-level edge quality.

High-speed bending cell bends small and medium-sized parts dynamically

and extremely cost-efficiently with the fastest system in the world.

Automated vertical CNC Machining Center features a high speed, 20 piece automatic tool changer.

Fully automated CNC production lathe enables the ability to hold tight tolerances and eliminates the need for separate finishing or grinding operations. Industry-leading OSP-P creates optimal operating efficiency.

Complete versatility, punch, bend, tap and form all on a single machine. The ultimate in flexible production to handle complex, three-dimensional parts and the ability to form flanges up to 75 mm high.

• Up to 505 hits per minute

• Tapping

• Forming, up to 3” flange

• Large tooling capacity

• Auto sheet load/unload

• 24/7 continuous running capabilities