Tag: aerospace

-

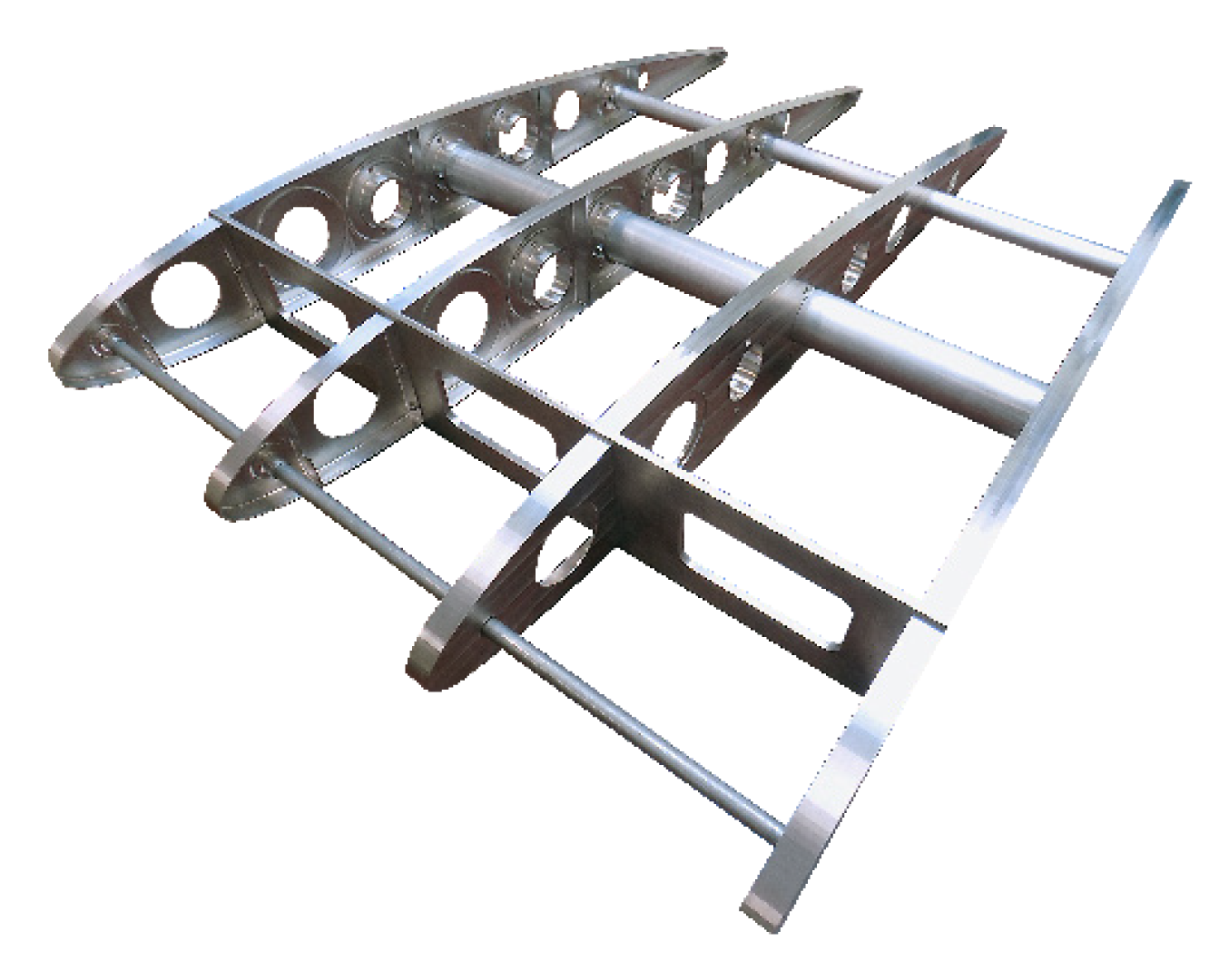

Astrostrike by Astroseal and Chapco

Nearly all composite aircraft make use of Astrostrike® for both shielding and lightning protection on large areas of the fuselage, wings, empennage, stabilizers, engine nacelles, propellers, winglets and the rotor blades. It was selected after comparison with seven alternative technologies for reasons of functionality and protection performance.