The benefits of in-house product development engineers at Chapco

Chapco’s dedicated team of

Located in Chester, CT, Astroseal Products Manufacturing Corporation is the developer of Astrostrike®. Nearly all composite aircraft make use of Astrostrike for both shielding and lightning protection on large areas of the fuselage, wings, empennage, stabilizers, engine nacelles, propellers, winglets and the rotor blades.

In 1983, Astroseal Products Manufacturing Corporation began developing Astrostrike®. The initial product, CU 040, was selected for use on the Bell/Boeing V-22 Osprey tilt-rotor aircraft.

Since then, nearly all composite aircraft make use of Astrostrike® for both shielding and lightning protection on large areas of the fuselage, wings, empennage, stabilizers, engine nacelles, propellers, winglets, and the rotor blades. Astroseal® has built a reputation for innovation, quality, and excellent customer service.

Finding a local manufacturer that had first hand experience with manufacturing parts for the aircraft/aerospace industries who had the right facilities, equipment, and capable staff to support this new project. When Randy from Astroseal approached Chapco for assistance, production deadlines, budgets, and on-time delivery were at risk.

Chapco was able to utilize its experience and expertise in aerospace fabrication and value-added capabilities, as well as its dedication to high-quality work, delivered on time, allowing Astroseal to stay true to its production schedules, budget, and expectations.

Chapco’s vast experience with CNC machining, sheet metal fabrication, and working with specialized metals provided Astroseal with competitive pricing, qualified production, engineering support, and on-time delivery.

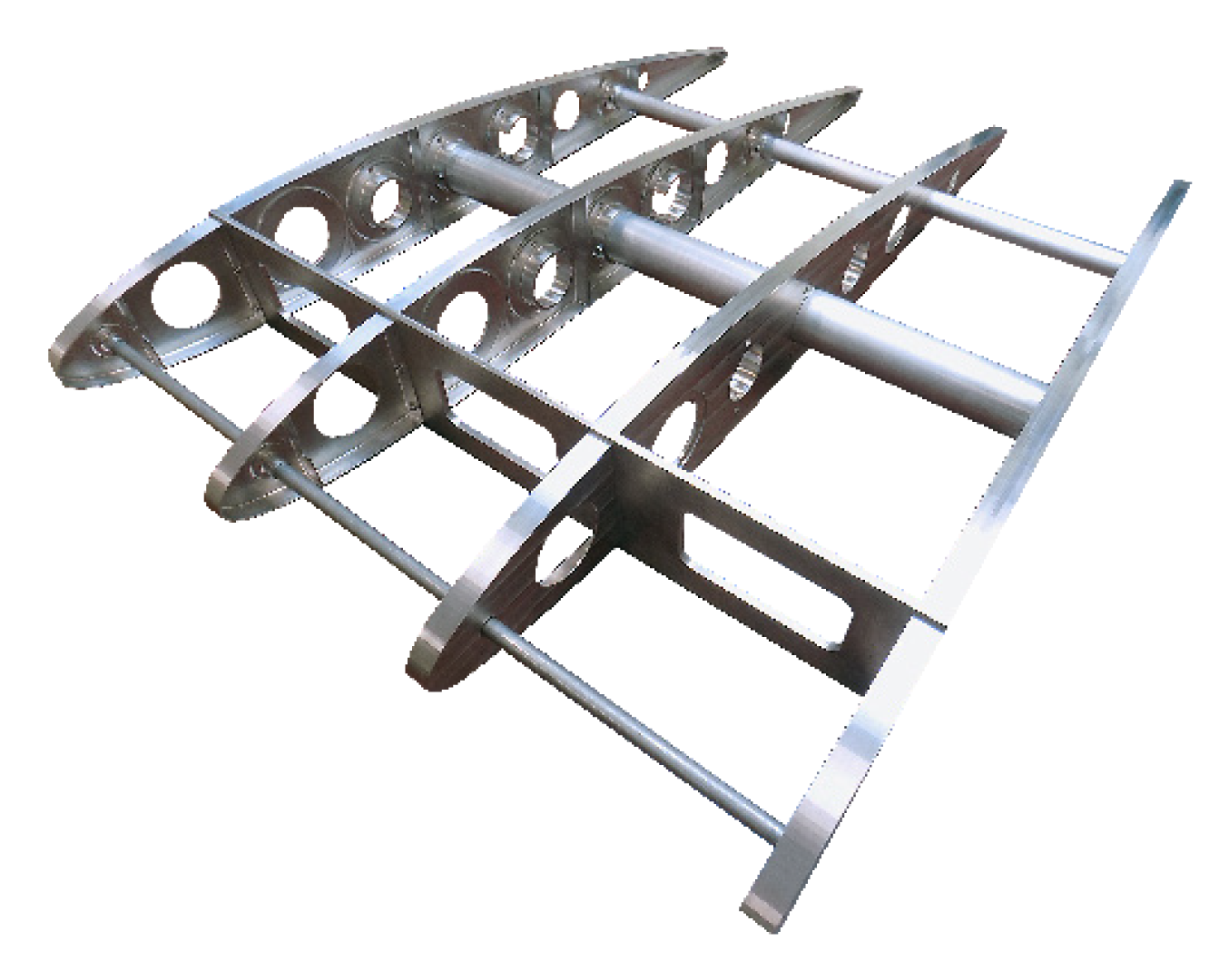

After coming aboard the team at Astroseal and heading the new product development project, Randy wanted to find a reputable local manufacturer that had the experience, equipment, and skill set needed to build a scaled-down air-foil model for a new product prototype concept. The prototype also needs to be manufactured to withstand the rigorous testing procedures it would have to go through for approval. Randy was also looking for a more streamlined and economical way to develop the prototype from earlier attempts.

After thorough research of local Connecticut manufacturers and multiple recommendations from colleagues, Chapco was the clear choice for this type of fabrication, and product development project

Chapco’s dedicated team of

The position of Sheet Metal Technician Level 1 supports production by bending, fastening, assembling and performing secondary operations on metal products. Equipment includes but is not limited to spot welding, power press, PEM equipment, AccuPress, Strippit Press.

Chapco, Inc., is celebrating 60 years of manufacturing partnerships, not just parts. Come celebrate with tours, product demonstrations, Oktoberfest refreshments, and live music.