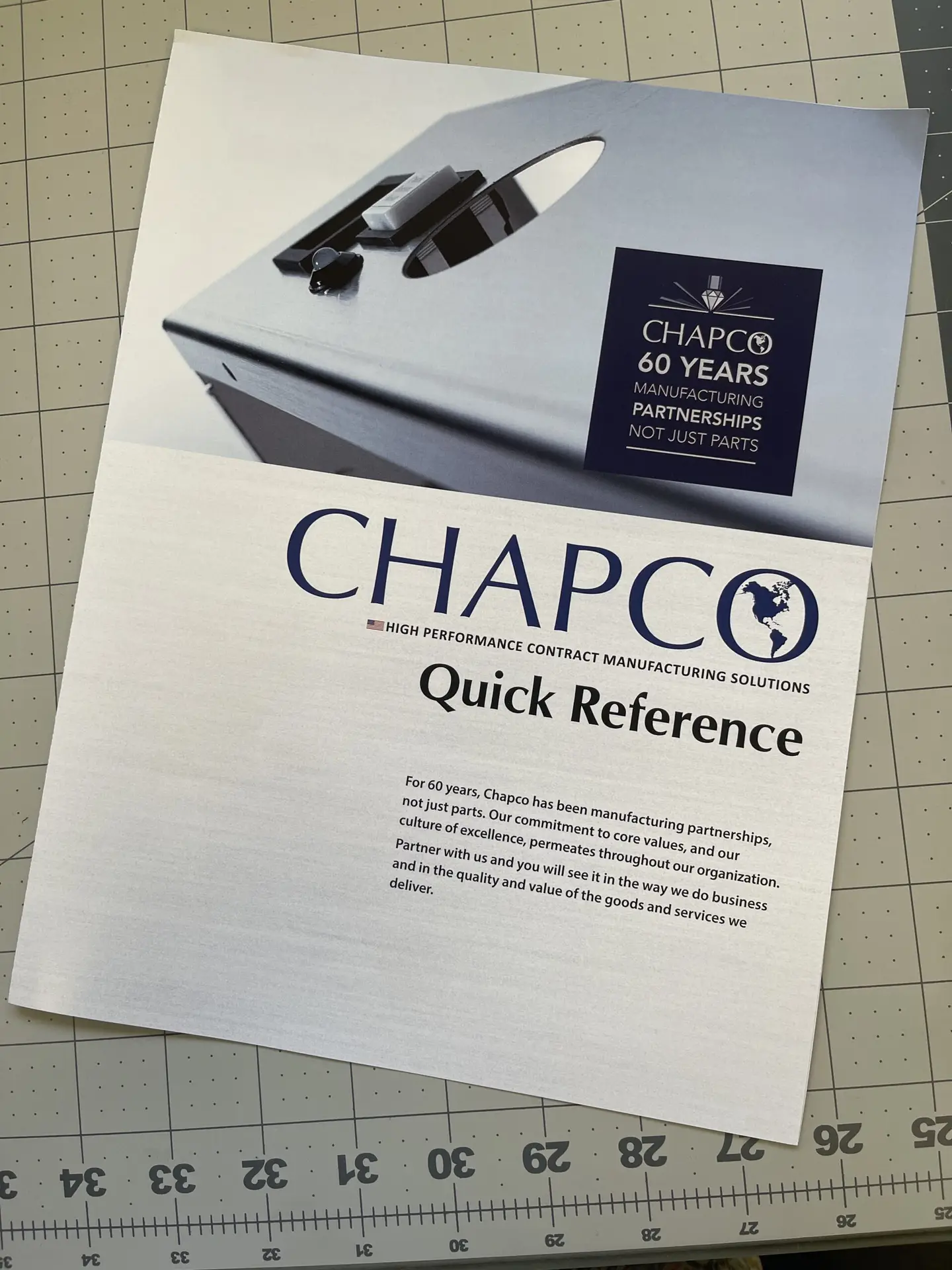

Chapco’s Quick Reference Guide for Engineers

Chapco is a Southeastern CT-based Sheet Metal Fabricator and Contract Manufacturer specializing in high-performance, tight tolerance, complex fabrication projects and high-volume production.

For over 60 years, we have invested in the best technologies, which we run 24/7 to scale to your needs. We offer a turn-key manufacturing operation from two sites in Chester, totaling 70,000 sqft of manufacturing facilities with 80+ staff working two shifts.

ENGINEERING SOLUTIONS

- From concept and prototype through production

- Product development in SolidWorks

- Coordinate/facilitate agency testing

(UL, ETL, NSF, NAMA) - Design with ease of manufacturing

- Efficient prototyping

- Value-added engineering

- Failure modes and effects analysis

- Testing and product fabrication

YOU MAY ALSO BE INTERESTED IN:

In the ever-evolving world of sheet metal manufacturing, staying ahead of the curve is not just a competitive advantage – it’s a necessity.

Re-shoring Sheet Metal Fabrication

Re-shoring Sheet Metal Fabrication, Contract Manufacturing A reassuring discussion about the pros and cons of re-shoring Introduction In the current global economic landscape, tariffs on

New Faces

New Faces at Chapco Some new faces, and some that have not yet been properly introduced! Welcome Christina Billings, Mike Cocuzza, and Mark Madore, to

QuickStep Marine

Quick Step Marine Take a look at the workmanship! https://youtube.com/shorts/aSh-dZoMF_c?si=gDUnT5-1k-ddMY-A

integrated UVC solutions

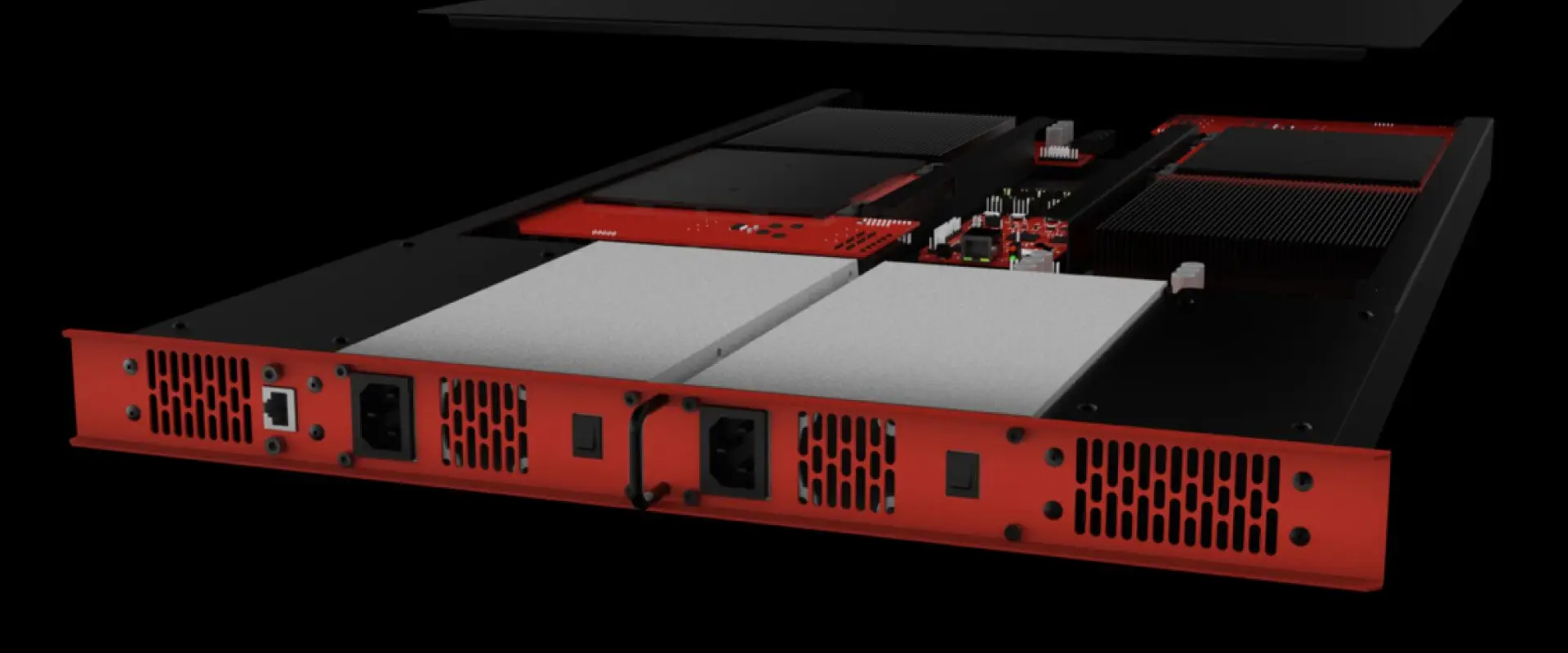

Chapco, inc. is the contract manufacturer for iUVC solutions’ ground breaking Spectra 1000 UV-C air and hard surface disinfecting solution. From design to sheet metal production and contract assembly, Chapco get’s the job done!

AWS Certifications

CONGRATULATIONS TO OUR WELD TEAM The American Welding Society recently certified our weld team with the following approvals: Specification Status 3/16″ 16ga CS MIG (D1.3)