Tag: Engineering

-

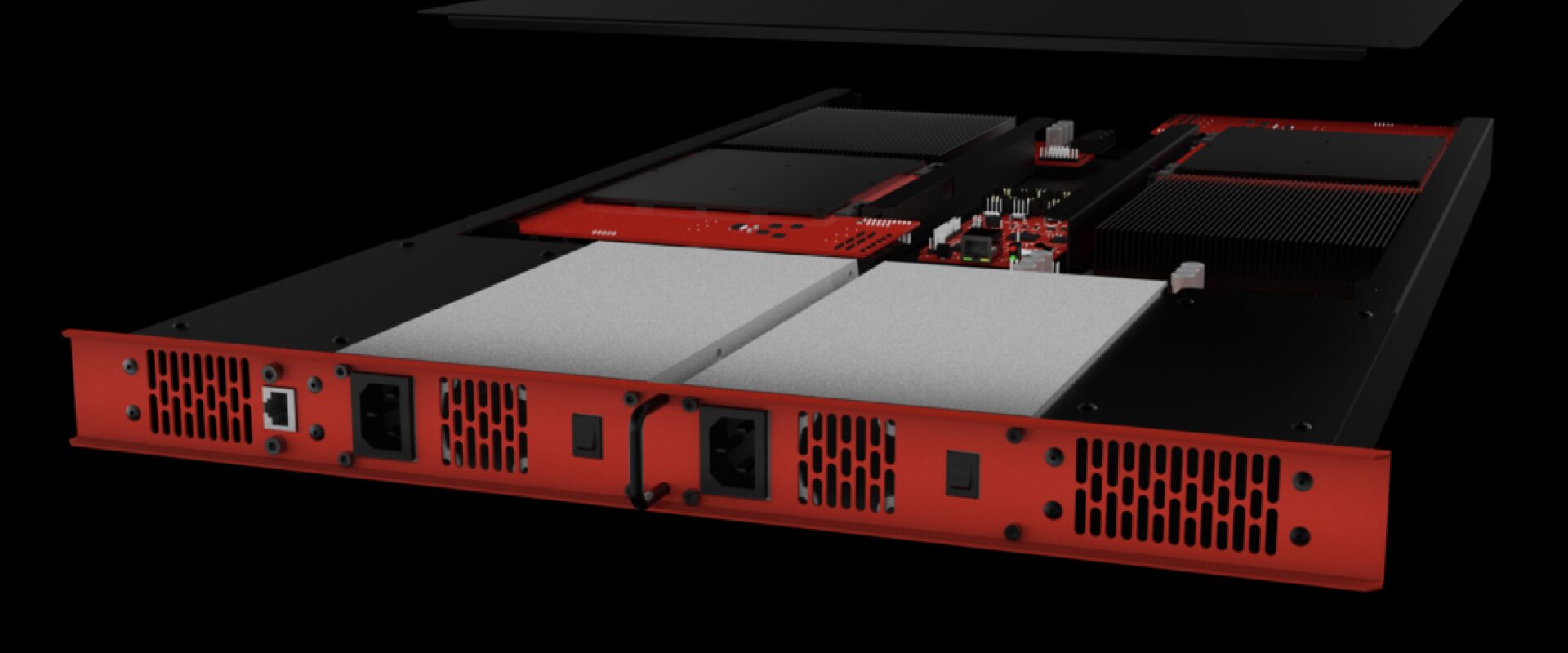

Chapco Ideaz & Obelisk®

Chapco Ideaz & Obelisk – a fabrication dream team: Cryptocurrency has been hailed as one of the next great technological revolutions, offering a critical pathway to transactional decentralization and security in a global cyber-economy that continues to evolve faster than many ever thought possible [Ideaz]

-

Chapco and Hydro-Hitch®

Saratoga Safeguard Solutions, LLC, home of the Hydro-Hitch®, was established in 2005 with over 33 years of experience in fire fighting and waterworks industries. With an extensive and ever-growing number of specialized products for water control and fire fighting operations Saratoga Safeguard Solutions, LLC has built a reputation for innovation, quality, and excellent customer service.