Category: Contract Assembly

-

integrated UVC solutions

Integrated UVC Solutions

Introducing state of the art supplemental disinfection devices for hospitals and medical facilities from our partners at iUVCs proudly manufactured by Chapco, inc – sheet metal and contract manufacturing services.

-

60 Years of Chapco’s Contribution to CTs Manufacturing Base

60 Years of Chapco’s Contribution to CTs Manufacturing Base

CHESTER, CT, October 11, 2023 – Senator Richard Blumenthal (D-CT), Connecticut’s 33rd district State Senator Norman Needleman (D-CT 33), and Connecticut’s Chief Manufacturing Officer, Paul S. Lavoie, gathered to celebrate a significant milestone as Chapco, a prominent CT manufacturer, commemorated 60 years of precision manufacturing in Middlesex County.

CHESTER, CT, October 11, 2023 – Senator Richard Blumenthal (D-CT), Connecticut’s 33rd district State Senator Norman Needleman (D-CT 33), and Connecticut’s Chief Manufacturing Officer, Paul S. Lavoie, gathered to celebrate a significant milestone as Chapco, a prominent CT manufacturer, commemorated 60 years of precision manufacturing in Middlesex County.CHESTER, CT, October 11, 2023 – Senator Richard Blumenthal (D-CT), Connecticut’s 33rd district State Senator Norman Needleman (D-CT 33), and Connecticut’s Chief Manufacturing Officer, Paul S. Lavoie, gathered to celebrate a significant milestone marking 60 years of Chapco’s contribution to Connecticut’s critical manufacturing base.

Senator Norm Needleman (D-CT33) and Senator Richard Blumenthal (D-CT) celebrate 60 years of proud American manufacturing with members of the Weinstein family. Chapco, established in the mid-1960s by Charlie Hurd and Al Pross, underwent a remarkable transformation under the leadership of Robert (Bob) Weinstein and his son, Brian Weinstein, who currently serves as President. The company began in a small machine shop on Denlar Drive in Chester and has since grown to encompass 70,000 sq ft of advanced manufacturing facilities across two campuses in Chester.

Following a festive luncheon attended by customers, suppliers, local representatives, and the dedicated Chapco workforce, Senator Blumenthal highlighted the indispensable role played by manufacturers like Chapco in Connecticut’s economy and the nation’s critical defense infrastructure.

Blumenthal emphasized, “Other states may boast natural resources like uranium and gold mines or iconic landmarks such as the Grand Canyon, but in Connecticut, our true strength lies in our ‘really smart’ people. That’s our ‘secret sauce’. Submarines are the backbone of our defense capabilities, and manufacturers like Chapco are instrumental in ensuring their supremacy.”

Chapco proudly aligns with Connecticut’s thriving manufacturing ecosystem. “Our unwavering motto is ‘building partnerships, not just parts,’” expressed Weinstein. With a team of seasoned engineers, production technicians, and assembly personnel, Chapco provides comprehensive end-to-end services, encompassing testing, manufacturing, assembly, packaging, and fulfillment.

Paul S. Lavoie, Connecticut’s Chief Manufacturing Officer also toured both campuses and witnessed a myriad of products crafted by Chapco, all originating from sheet metal blanks. These products included Integrated UVC’s innovative no-touch air and surface disinfection system, Icleanse’s cell phone UV disinfection devise, Fastcorp Vending’s cutting-edge automated retail solutions for regulated products, Denlar Fire Protection’s integrated fire suppression range hood systems, and the TRUEFORM.RUNNER – treadmill of choice for NFL superstars and NASCAR Race Teams.

Lavoie, who leads the Office of Manufacturing, is dedicated to empowering manufacturers to leverage market opportunities and cement Connecticut’s status as the Silicon Valley of advanced manufacturing. “My mission is to showcase Connecticut,” Lavoie affirmed, “and companies like Chapco make that task much simpler.”

President of Chapco and its collaborative companies, Brian Weinstein emphasized their commitment to excellence, stating, “We’ve always believed in investing in the best technologies and operating 24/7. Our recent $1.6 million investment in a Trumpf Trumatic 6000 fiber laser punch combo underscores our dedication to meeting tight deadlines and ensuring the resilience of U.S. supply chains.”

Chapco’s six decades of unwavering dedication to precision manufacturing epitomize its commitment to advancing the Connecticut manufacturing landscape. As we celebrate their remarkable journey, we look forward to their continued contributions to our vibrant community and the nation.

Congratulations, Chapco, on this significant milestone!

YOU MAY ALSO BE INTERESTED IN:

Re-shoring Sheet Metal Fabrication

May 6, 2025 No CommentsRead More »Re-shoring Sheet Metal Fabrication, Contract Manufacturing A reassuring discussion about the pros and cons of re-shoring Introduction In the current global economic landscape, tariffs on

New Faces

March 3, 2025 No CommentsRead More »New Faces at Chapco Some new faces, and some that have not yet been properly introduced! Welcome Christina Billings, Mike Cocuzza, and Mark Madore, to

QuickStep Marine

March 3, 2025 No CommentsRead More »Quick Step Marine Take a look at the workmanship! https://youtube.com/shorts/aSh-dZoMF_c?si=gDUnT5-1k-ddMY-A

integrated UVC solutions

March 3, 2025 No CommentsRead More »Chapco, inc. is the contract manufacturer for iUVC solutions’ ground breaking Spectra 1000 UV-C air and hard surface disinfecting solution. From design to sheet metal production and contract assembly, Chapco get’s the job done!

AWS Certifications

March 3, 2025 No CommentsRead More »CONGRATULATIONS TO OUR WELD TEAM The American Welding Society recently certified our weld team with the following approvals: Specification Status 3/16″ 16ga CS MIG (D1.3)

-

Chapco, Inc. continues to invest; adds new $1.6m “lights out” technology

Chapco, Inc. continues to invest; adds new $1.6m “lights out” technology

CHESTER, CT, June. 2, 2023: Chapco has announced an additional $1.6m manufacturing investment in the CT Economy for automated work centers at its Denlar Dr., Chester, facility.

CHESTER, CT, June. 2, 2023: Chapco has announced an additional $1.6m manufacturing investment in the CT Economy for automated work centers at its Denlar Dr., Chester, facility.CHESTER, CT, June. 2, 2023: Chapco has announced an additional $1.6m manufacturing investment in the CT Economy for automated work centers at its Denlar Dr., Chester, facility.

Chapco, Inc. is a high-performance metal fabrication and contract manufacturing company. Established in 1964, Chapco’s 80+ employees deliver high-performance metal fabrication solutions to customers from diverse industries across the Northeast Region. Their innovative processes, superior customer service, and single-source capabilities have attracted leading manufacturers in Connecticut, from medical devices and defense to automated retail.

“The addition of the Trumatic 6000 continues our major investment program to improve Chapco’s metal cutting, punching, and bending capabilities,” explains Chief Operations Officer Craig Goodspeed. “We have targeted this investment to enhance Chapco’s position as a leading regional manufacturer.”

Chapco remains a family-owned and operated company. “Our commitment to core values and a culture of excellence permeates our organization. Anyone who partners with us sees it in how we do business and the quality and value of the goods we deliver,” says President Brian Weinstein. “We are very excited to have another state-of-the-art machining center installed here at Chapco. We have always believed in owning the latest and greatest technology and equipment. This additional investment allows us to continue to execute our growth plan in a tight labor market.”

The Trumatic 6000 fiber laser cuts, punches, forms, and engraves sheet metal up to 0.25 inches thick and is designed for scratch-free processing. It features an intuitive laser output control system to cut delicate curves and tight radii accurately and consistently. At the other end of the scale, this combo work center can exert 20 tons of punching force delivered at 1,000 strokes per minute and can run ‘lights out’ 24/7.

The productivity of the solid-state laser is most evident in galvanized mild steel and stainless steel. When cutting these materials, processing speeds are up to six times greater than with a CO2 laser of the same power. The solid-state laser also enables the Trumatic to process non-ferrous metals, such as copper and brass, in addition to mild steel, stainless steel, and aluminum. In addition, rapid tool changeover is affected through the linear magazine, which stores up to 23 tools.

Learn more about Chapco’s automated capabilities and download our brochure below.

YOU MAY ALSO BE INTERESTED IN:

Re-shoring Sheet Metal Fabrication

May 6, 2025 No CommentsRead More »Re-shoring Sheet Metal Fabrication, Contract Manufacturing A reassuring discussion about the pros and cons of re-shoring Introduction In the current global economic landscape, tariffs on

New Faces

March 3, 2025 No CommentsRead More »New Faces at Chapco Some new faces, and some that have not yet been properly introduced! Welcome Christina Billings, Mike Cocuzza, and Mark Madore, to

QuickStep Marine

March 3, 2025 No CommentsRead More »Quick Step Marine Take a look at the workmanship! https://youtube.com/shorts/aSh-dZoMF_c?si=gDUnT5-1k-ddMY-A

integrated UVC solutions

March 3, 2025 No CommentsRead More »Chapco, inc. is the contract manufacturer for iUVC solutions’ ground breaking Spectra 1000 UV-C air and hard surface disinfecting solution. From design to sheet metal production and contract assembly, Chapco get’s the job done!

AWS Certifications

March 3, 2025 No CommentsRead More »CONGRATULATIONS TO OUR WELD TEAM The American Welding Society recently certified our weld team with the following approvals: Specification Status 3/16″ 16ga CS MIG (D1.3)

-

Chapco Capabilities Brochure 2024

Chapco Capabilities Brochure 2024

We take pride in our expansive infrastructure, boasting two state-of-the-art locations encompassing a total of 70,000 square feet, and we would also love to host a visit by your team.ARRANGE A CALL

YOU MAY ALSO BE INTERESTED IN:

In the ever-evolving world of sheet metal manufacturing, staying ahead of the curve is not just a competitive advantage – it’s a necessity.

Re-shoring Sheet Metal Fabrication

May 6, 2025 No CommentsRead More »Re-shoring Sheet Metal Fabrication, Contract Manufacturing A reassuring discussion about the pros and cons of re-shoring Introduction In the current global economic landscape, tariffs on

New Faces

March 3, 2025 No CommentsRead More »New Faces at Chapco Some new faces, and some that have not yet been properly introduced! Welcome Christina Billings, Mike Cocuzza, and Mark Madore, to

QuickStep Marine

March 3, 2025 No CommentsRead More »Quick Step Marine Take a look at the workmanship! https://youtube.com/shorts/aSh-dZoMF_c?si=gDUnT5-1k-ddMY-A

integrated UVC solutions

March 3, 2025 No CommentsRead More »Chapco, inc. is the contract manufacturer for iUVC solutions’ ground breaking Spectra 1000 UV-C air and hard surface disinfecting solution. From design to sheet metal production and contract assembly, Chapco get’s the job done!

AWS Certifications

March 3, 2025 No CommentsRead More »CONGRATULATIONS TO OUR WELD TEAM The American Welding Society recently certified our weld team with the following approvals: Specification Status 3/16″ 16ga CS MIG (D1.3)

-

Chapco Ideaz & Obelisk®

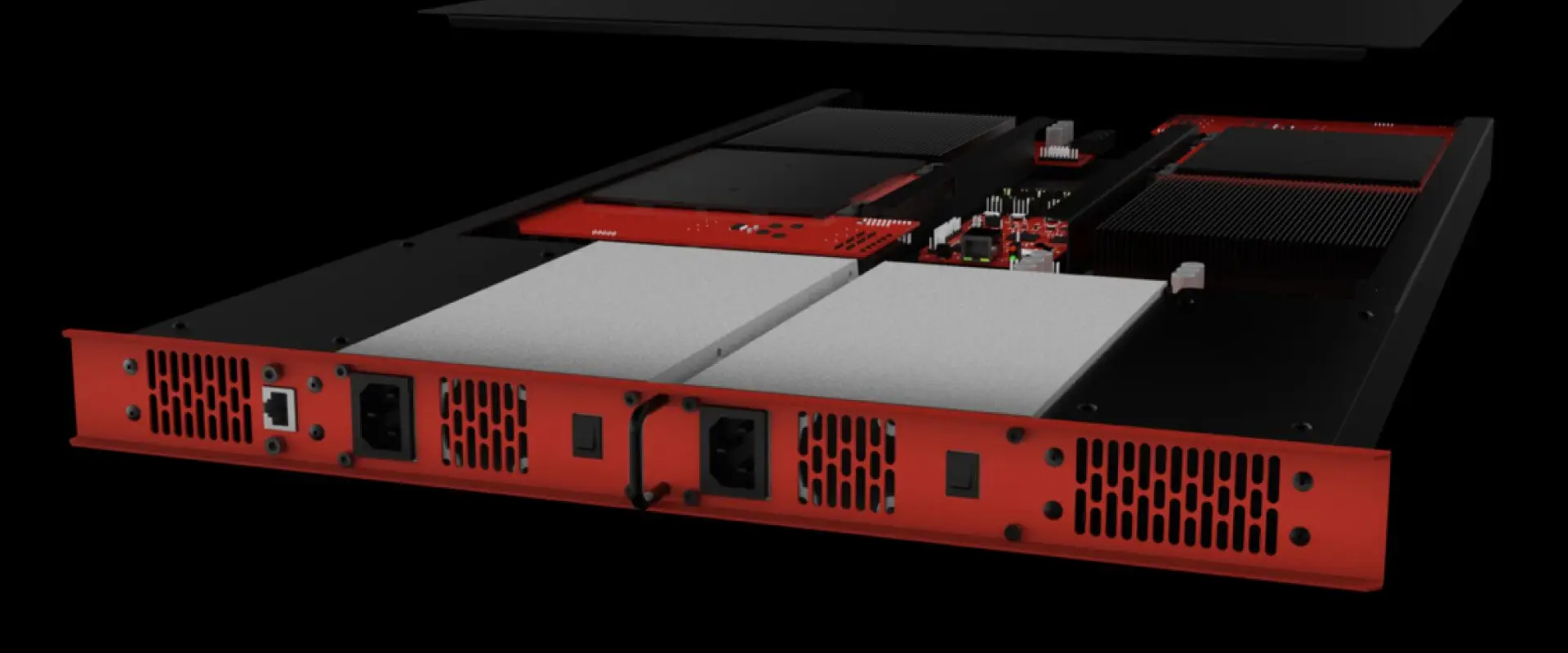

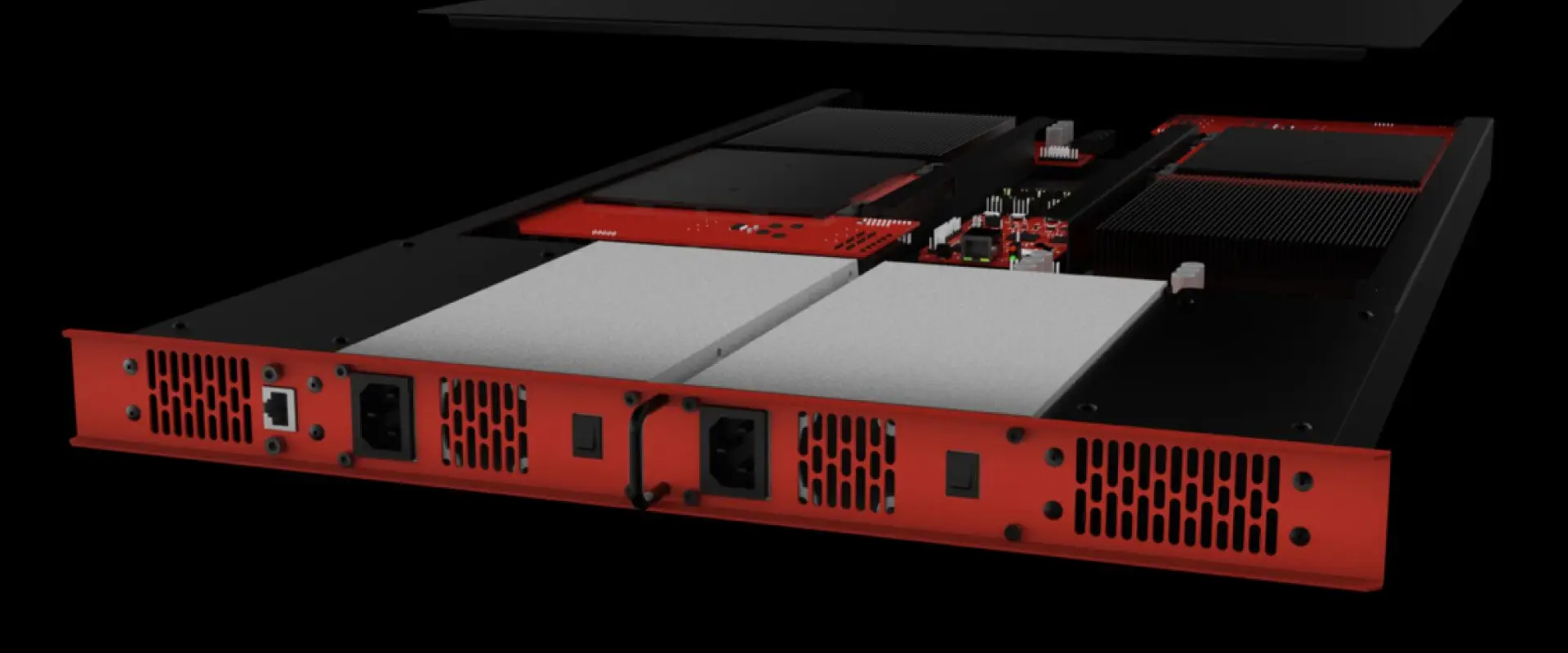

all photos courtesy of IdeazChapco Ideaz & Obelisk – a fabrication dream team: Cryptocurrency has been hailed as one of the next great technological revolutions, offering a critical pathway to transactional decentralization and security in a global cyber-economy that continues to evolve faster than many ever thought possible [Ideaz]

all photos courtesy of IdeazChapco Ideaz & Obelisk – a fabrication dream team: Cryptocurrency has been hailed as one of the next great technological revolutions, offering a critical pathway to transactional decentralization and security in a global cyber-economy that continues to evolve faster than many ever thought possible [Ideaz]Chapco Ideaz & Obelisk®

In June 2017, Obelisk, Inc. launched with the goal of moving the cryptocurrency mining industry towards a future enshrined in transparency, stability, and healthy competition. In early 2018, Obelisk partnered with Ideaz mechanical and electrical design teams to develop their flagship products.the project

Obelisk and Ideaz were working against an extremely aggressive development timeline of just a few months until production units needed to ship to customers. Their mechanical and electrical engineers collaborated to design the electromechanical chassis assembly, and then worked closely with Chapco’s engineers and production team to ensure a smooth process from quote to delivery.the challenge

Chapco’s team offered value-added engineering services to ensure cost-effective manufacturing to meet our clients’ target pricing.

Following prototyping, Chapco was able to employ our automated work centers to ensure we met our clients’ aggressive time line

the solution

Production processes included laser cutting, custom punching, robotic and conventional bending, as well as hardware insertion. Obelisk’s first production order was for 2000 kits, with each kit consisting of 5 parts. 10,000 parts were completed in 4 weeks. Three further orders followed for 2000 kits per order. All 8000 kits were completed in 16 weeks.Images courtesy of Ideaz and Obelisk

The future

Since their founding just a few years ago, Obelisk has already shipped thousands of mining units, which have generated tens of millions of dollars in revenue, and they continue to reach new customers every day. In a rapidly evolving industry where development happens in weeks, not years, and success is predicated on always being a step ahead of the competition. Obelisk has now developed into Foundation Devices.Whether this is your first fabrication project, or one of the hundreds you are managing this month, our custom sheet metal fabrication capabilities will set your mind at ease. We have the people, equipment, and facility to offer a full range of metal fabrication and customization to bring nearly any design to reality.David PaullChief Revenue Officer We pride ourselves on only committing to what we can do, and always delivering on what we promise.Brian WeinsteinPresident, Chapco Inc.

We pride ourselves on only committing to what we can do, and always delivering on what we promise.Brian WeinsteinPresident, Chapco Inc. PreviousNext

PreviousNextShare Post:

Stay Connected

READ MORE ABOUT CHAPCO’S PARTNERSHIPS

We are Chapco

We are Chapco For nearly 60 years, Chapco has been a member of Connecticut’s thriving manufacturing industry. Learn more about who we are, and what

March 3, 2025

Steely Motivation

signs to motivate, celebrate, and elevate manufactured with pride in Connecticut, USA from #4 polished Stainless Steel

November 21, 2024

In-house product development at Chapco

Chapco’s dedicated team of

in-house engineers ensures superior client satisfaction by seamlessly integrating design and production processes. With our expert engineers onboard, Chapco delivers exceptional value, enhancing outcomes for both the company and its clients.February 15, 2024